- Home

- About Us

- Products

- For Battery Manufacturing

- Grid Panels And Component Moulds

- Component Casting Machines

- Trim And Planishing Dies

- Panel Acid Wash Conveyors / Acid Pickling Units

- Flash Drying Oven - Gas Fired or Electrically Operated

- Group Making & Burning Station

- Hole Punching Machine and Tools

- Battery Plate Processing

- Heat Sealing Machines

- Lid Chamber Sealing Machines

- Intercell Welding Machines

- Short Circuit Testing Machines

- Acid filling Machine for all variants

- SPM & Industrial Automation

- For Battery Manufacturing

- Gallery

- Contact

- Enquiry

- Location We Serve

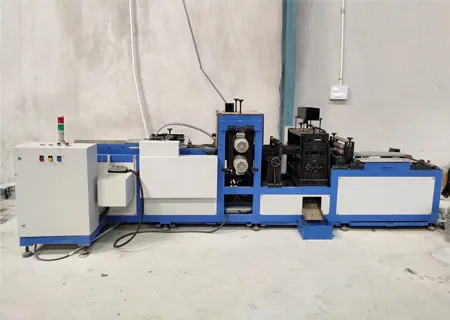

LBCM (X direction) machine for Automotive and Motorcycle Battery Manufacturer

- Home

- LBCM (X direction) machine for Automotive and Motorcycle Battery Manufacturer

We are Manufacturer, Supplier, Exporter and Services Provider of LBCM X Direction Machine for Automotive and Motorcycle Battery and Our Setup situated in Pune, Maharashtra, India

GAES is manufacturing and supplying high quality Battery Plate Lug Brushing and plate cutting machine for Automotive and Motorcycle Battery (LBCM) with reasonable price.

We are manufacturing & supplying two types of LBCM machine for Automotive & motorcycle batteries;

- Battery Plate Lug Brushing and plate cutting (X direction) machine for Automotive and Motorcycle Battery.

- Battery Plate Lug Brushing and plate cutting (X-Y direction) machine for Motorcycle Battery

Fully automatic LBCM machine is manufactured to ensure quality of brushing and cutting/parting of panel considering higher productivity.

Machine Features

- Sufficient long feeder unit to stack panel for processing ( 400 to 450 panels)

- Well designed, Vacuum picks up unit to pick & drop single panel for brushing and cutting.

- For safer side, sensors are provided to avoid double panel feeding to avoid rejection.

- Speed of machine is variable/adjustable

- After cutting unit, proper stacking arrangement for plates has been provided to ensure proper collection and reduce operator fatigue.

- PLC based operation to ensure smooth and user friendly operation of machine.

Machine Specifications:

| Machine Speed | 110 panels for X cutting 80 panels/mins for X-Y cutting |

Panel Size |

Width - 180 to 320 mm (Considering lug) |

Input Supply |

3 Phase, 415 V, 50 Hz |

Power Requirement |

6 HP (For X Cutting) 8 HP (For X-Y Cutting) |

| Exhaust Requirement | 6000 m3/hrs (Optional, if canopy required) |

Machine Size : |

4000 X 1.5 X 1.5 (For X Cutting) |